GCSE OCR Gateway Organic

Chemistry C6.2i

Summary

Common misconceptions

Carbon chemistry is the basis

of life on Earth. Organic chemistry is the basis of many of the materials we

produce. Organic compounds are covalent in nature and react in a predictable

pattern. Crude oil forms the basis of many useful by-products.

CM6.2i To be able to represent

three-dimensional shapes in two dimensions and vice versa when looking at

chemical structures, e.g. allotropes of carbon.

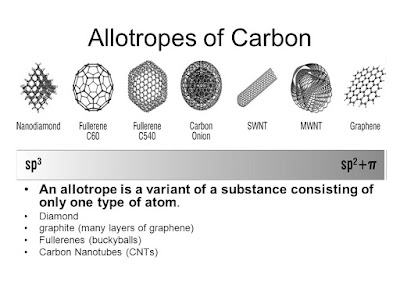

Allotropes

of carbon

Allotropes are different

structural forms of the same element in the same physical state.

Carbon has several allotropes

in its solid state: Diamond, Graphite , graphene, fullerenes and nanotubes.

Diamonds

Graphite

Buckminsterfullerene C60 (dissolved

in benzene)

flakes of graphene welded

together

Allotropes of carbon are based

on the ability of carbon to demonstrate three dimensionality.

Each carbon atom can form up

to four covalent bonds with itself or with other elements.

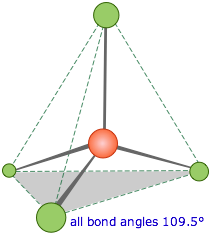

When carbon forms four

covalent bonds with itself, it forms a diamond structure. Each bond points to the corner of a regular

tetrahedron as in the diagram below.

The covalent

bonds are very strong they require massive amounts of energy to break them all

and so when combined in the giant diamond structure give diamond its incredible

hardness and strength.

Diamond is

the hardest known material. Hence it is used in drill bits. It will easily cut glass.

As all the

outer shell electrons of the carbon atoms are used in the four bonds there are

no delocalised electrons to allow for the conduction of electricity so carbon

as diamond is an insulator.

Breaking

these strong covalent bonds as I have said requires massive amounts of energy

and so the material is insoluble in water.

On the other

hand carbon atoms in graphite are bonded differently. Unlike in carbon there are only three bonds

per carbon atom n graphite.

Each bond is

a very strong covalent bond but as there are only three per carbon atom then

the carbon atoms are arranged differently to diamond.

In graphite

the carbon atoms are arranged in layers.

The diagram below shows how this happens:

As a result

each carbon atom has a delocalised electron to contribute to the conduction of

electricity in graphite. Graphite is

good conductor of electricity.

The layers

repel each other too and are loosely bonded to each other so that they are able

to slide over each other. Hence,

graphite is a smooth and slippery substance and is used in lubricants. For the same reason, it is also found in

pencil “lead” where it is baked with varying amounts of clay to give different

degrees of softness to the “lead”.

Graphene is

related to graphite since it is composed of a single layer of carbon atoms like

those found in graphite.

Fullerenes

on the other hand and single wall nano tubes are formed as if the grapheme layer

of carbon atoms had been rolled into a tube (SWNT) or folded up into a ball

(fulllerenes)

You can see

this from the diagram below:

This final

chart summarises the properties of the carbon allotropes